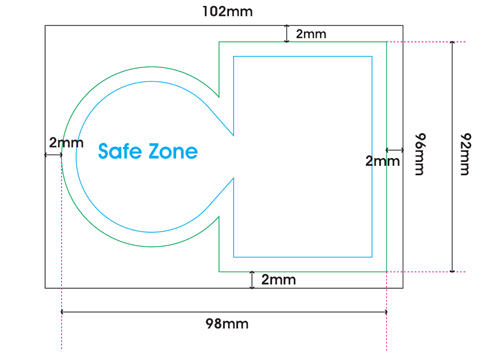

SAFE ZONE, BLEEDING, DIE LINE

Example :

Input the artwork actual size at Ordering Page when you place order.

Let’s say your artwork = 98mm x 92mm

-

Actual Artwork Size *(Die Line)

98mm x 92mm

-

Full Bleed Size (must add 4mm from order size)

102mm x 96mm

-

Safe Zone

2mm from all sides of die-cut edge

* Die line must same with order size

Example 1:

Example 2:

IMPORTANT NOTES FOR WASTE REMOVAL FINISHING

Artwork with square & rectangle shape MUST require minimum 2mm radius edge (round corner)

PREPARING FILE FOR LABEL STICKER WITH DIE LINE ARTWORK SPECIFICATION

DIE LINE PRECAUTIONS

Cutting Edge Tolerance: + -1mm

Below are mis-registration scenario that can be happen during the die-cut process when die lines is not correctly placed,

as + -1mm cutting edge tolerance has to be taken into consideration.

-

Scenario 1 :

What happens when die line falls exactly on the artwork line.

-

Scenario 2 :

What happens when die line is exactly on different colour background

-

Member is advised to revise artwork when these problem are detected.

-

Excard shall not be held liable for any of defect in printing outcome due to artwork sent not correctly prepared as advised.

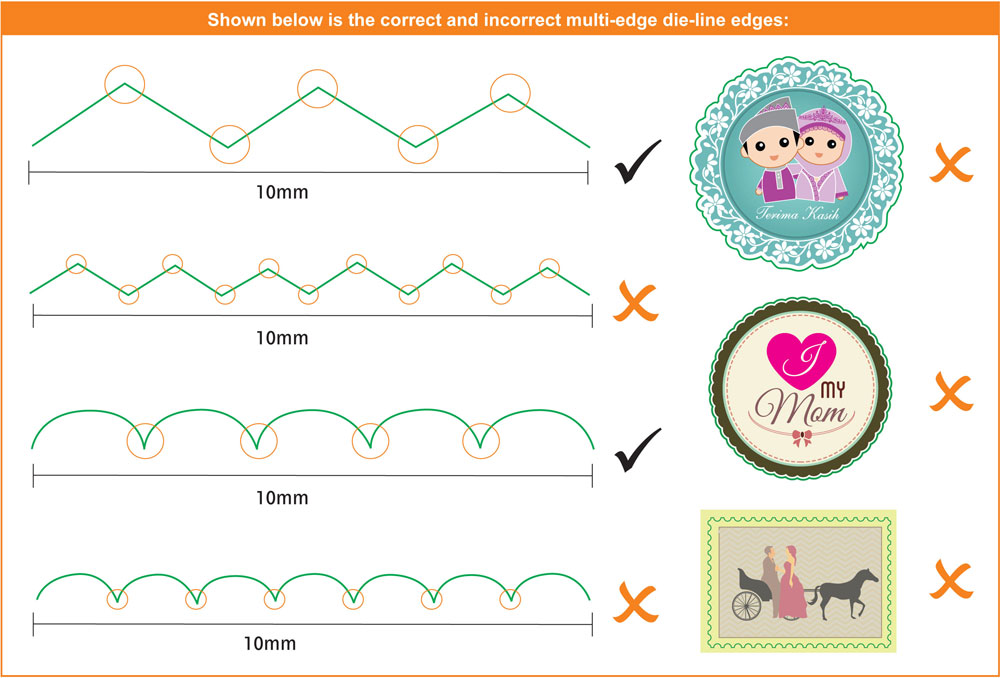

GAP BETWEEN MULTI-EDGES DIE LINE

How to define “Multi-Edges Die Line” - More than 5 cutting edges within 10mm.

1 COLOUR LABEL STICKER

Artwork with toning from 10% - 100% is allowed for 1 colour label sticker.

For example:

WHITE COLOR PRINTING

White color is only available for OPP and not available for other stickers. Printed stickers will show white color

due to sticker surface color are white (MKPS, PRPS, PPNG and SYPR).

Yet for Transparent OPP sticker , since it is transparent, so printing without white ink will be see through if

paste on colored surface.

ARTWORK PREPARATION FOR OPP WITH WHITE INK

For order with 4C + White

Page 1: Overview artwork (Printable artwork and Dieline)

Page 2: White artwork with Process Black Colour (K100) - rename to “White”

Page 3: Printable artwork only (CMYK)

Page 4: Dieline only

For order with White (1C)

Page 1: Overview artwork (White artwork and Dieline)

Page 2: White artwork with Process Black Colour (K100) - rename to “White”

Page 3: Dieline only

Finishing Cut To Size

Page 1: White artwork with Process Black Colour (K100) - rename to “White”

Page 2: Printing artwork

IMPORTANT NOTES IN PREPARING WHITE BASE ARTWORK

-

Fill the artwork with black (K100) to indicate the area for white base.

-

Rename colour to precisely “ White” to indicate the area of white base instead “WHITE” or “white”

*Excard will not held responsibility on any wrong white spot colour naming error. .

(eg. “WHITE” or “white” or “White(space)” )

-

Only use Adobe Illustrator to prepare the white base artwork

-

JPEG file format or JPEG save in PDF format is not allowed while prepare white based artwork.

-

White based artwork must prepare in VECTOR

Rename the color swatch name by using Adobe Illustrator

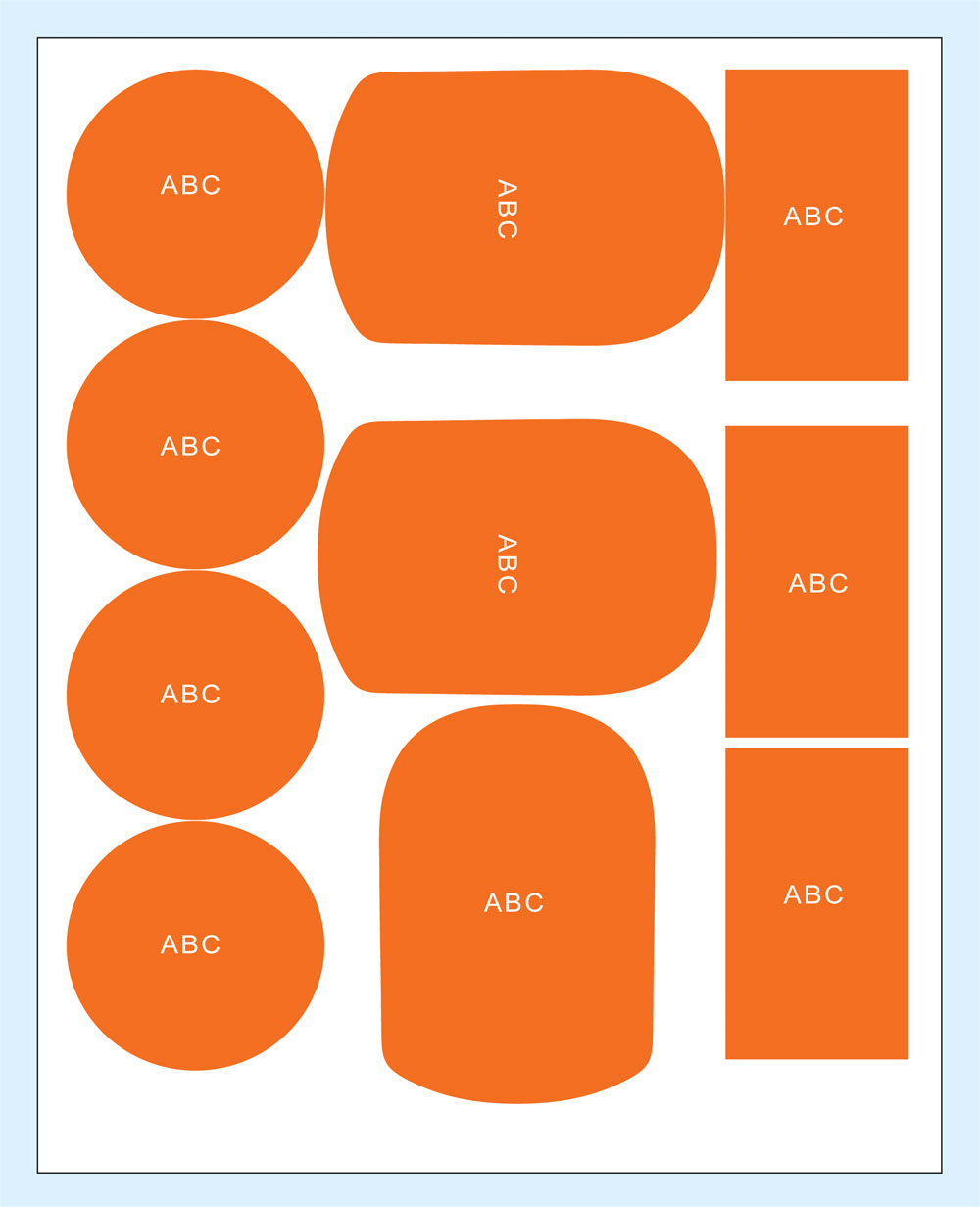

MULTIPLE DIE LINE LABEL STICKER

Artwork Dimension ( Refer to diagram)

Please refer to the diagram below for the artwork dimension. For example, A4 size:

|

1.5mm bleeding for artwork

|

|

Die cutting size for artwork

|

|

2mm safe zone for artwork

|

|

10mm safe zone for cut to size sticker

* Order size minus 20mm.

Example : Width: 210mm - 20mm = 190mm ;

Height : 297mm - 20mm = 277mm

So total size for safe zone is = 190mm x 277mm

|

|

Sticker product size

|

|

* The gap between 2 trim lines must at least 3mm

|

MULTIPLE DIE LINE LABEL STICKER ARTWORK FILE PREPARATION METHOD

Page 1 : CMYK Printing + Die Line

Page 2 : CMYK Printing

Page 3 : Die Line